When evaluating what path to choose for our cooling infrastructure at TRG, we had to take many different considerations into account.

The primary considerations were as follows:

- Reliability

- Modularity

- Flexibility

- Efficiency

With reliability as our focus and core service offering, we evaluated 15 different products and cooling methodologies including indirect economized systems, chiller-based systems and modular DX products. We ran tests for fault tolerance and concurrent maintainability in all aspects of the system, as required by The Uptime Institute, and found that utilizing chiller-based systems creates major challenges due to their respective piping infrastructure.

Most data centers utilize a “chiller loop” which achieves concurrent maintainability, but generally falls short of fault tolerance without a significant amount of additional infrastructure investment. The fact that each Liebert DSE has its own direct connection to independent condensing units allowed us to easily check the box for fault tolerance without all the complications and headaches that come with a chiller infrastructure or chiller plant. The Liebert DSE is a much simpler system and minimizes failure probability while adding true reliability.

Another important consideration was modularity. As a colocation, with ever-changing load requirements, the Liebert DSE offers us scalability: the option to add units as our load increases. This modularity reduces our initial infrastructure investment requirements, which translates to savings for our clients.

Flexibility fits with the modularity story, but for different reasons. We visit many facilities where common chiller system load requirements have changed and resulted in a low delta T and loss of energy in the facility. The ability to synchronize the controls between the Liebert units allows us to accurately service our clients even when there are mixed loads of high and low densities.

Finally, in regards to efficiency, we are continually impressed by the partial load capabilities of the Liebert DSE. Houston is a challenging environment, and these units have unprecedented levels of control over airflow and cooling with the split-tandem compressor design. There are few products on the market that allow this level of capability. The Liebert DSE is easily retrofitted with the pumped refrigerant economization option that allows for continual flexibility in the challenging, hot and humid Houston climate. We plan to implement these systems in the future. Liebert makes continuous updates on the controls of these systems making them more efficient and perpetually competitive with today’s IT technology.

Arriving at a decision to utilize the Liebert DSE product involved many iterations of engineering and design, benchmarking system performances against myriad other products. The BGA team was key in utilizing the tools and resources that they had to show us the full capabilities of the system. Their experience and depth of talent with the Liebert product line goes far beyond what we have in house, and ultimately was a major decision-making factor for us as we were able to augment our team using them as an extension.

To this day, the DSE product continues to show new capabilities and configurations with its advanced controls capabilities, and we are enjoying our continuing relationship with the BGA team in fine tuning this. We have learned a lot about the system and continued to improve our configurations in ways that we would not have been able to alone.

With mechanical cooling systems being one of the three largest considerations in your data center infrastructure, we feel confident having the BGA team standing behind TRG as we scale our product offering.

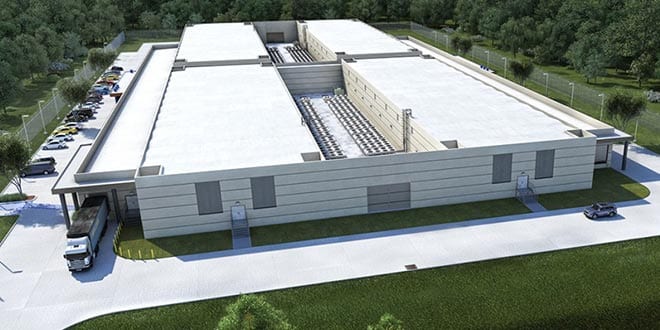

Visit the TRG website for more details on their data center.